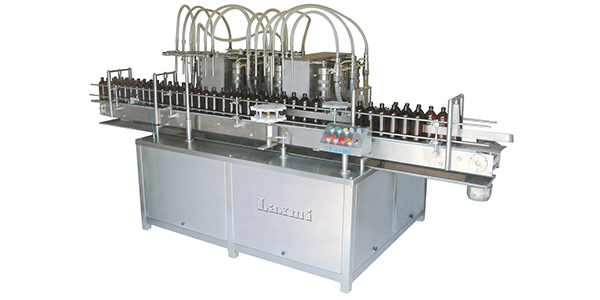

We Laxmi Pharma, are among the reputed names in the industry for manufacturing and Oral Liquid Filling Machine Equipment, which is used in different types of machines. Buy machine, all bottles are manual / automatically loaded on a turn table/conveyor where the Liquid gets filled in a series of operations by drive-in type. You will get many oral liquid-filling machine bottle manufacturers, but Laxmi Pharma has provided you with high-quality products with guaranteed fulfillment. This machine is user-friendly and compact, it is a Volumetric type, SS 316 to PTFE type each Filling Pump, is suitable to fill 5ml to 1000ml with the help of a change part, etc.

Liquid filling machines are specialized equipment that are used in the pharmaceutical and nutraceutical industries for filling liquid substances into containers such as bottles, vials, and ampoules. Here are some uses:

In the pharmaceutical industry, machines for liquid filling are generally used for a variety of applications, including filling medicinal syrups like cough syrups and other liquids into bottles. They are also experts in filing sterile liquids into small vials, which are used for injections or oral intake. Additionally, these kinds of machines are utilized for dispensing antibiotics and vitamin-rich solutions in exact containers, ensuring precision and compliance with hygiene for maintaining the integrity and efficiency of the products.

Liquid filling machines are used for filling liquid dietary and herbal extracts into bottles or other containers, for ensuring the correct dosage and consistency of the liquid. These machines ensure the accurate filling of liquids and vitamins and also maintain the required dosage of accuracy to meet health and safety standards.

In this industry, machines are utilized for filling health drinks, energy shots, and liquid nutritional supplements into small containers or bottles. They are also used in dispensing liquid flavoring agents into different-sized containers, ensuring the precise filling to maintain product consistency and quality.

Oral liquid filling lines are employed for filling small bottles with essential oils, serums, and other liquid cosmetic products, as well as for the precise filling of perfumes and other fragrant liquids into the bottles. In this chemical industry, these machines are used for filling bottles with liquid cleaning agents and disinfectants for dispensing precise amounts of liquid chemicals for laboratory use, and also for safety in handling all potentially hazardous substances.

Here are some of the features that are included in the Oral Liquid Filling Machine or bottle fillers :

As per GMP,

An Automatic Oral Liquid Filling Machine is a complex and important piece of instrument that is designed to systemize and customize the precise filling of liquid products into bottles. This machine includes different types of key components, each of them are playing an important role in ensuring accurate dosing, efficiency, and conformity to regulatory requirements.

The reservoir is where the liquid products are stored before it is dispensed into the bottles. This component is typically constructed from high-quality materials. Stainless steel(SS 316) for maintaining the purity of the liquid and also preventing contamination. Hoppers may include features like agitation systems for keeping the liquid homogenous and also help in preventing settling.

Oral Filling heads or nozzles are the reason for dispensing the liquid into containers. These components are planned to give exact volumes of liquid to each box while minimizing foaming, splashing, or spillage. Depending on the machine’s design and production capacity, there may be different filling heads operating together to increase throughput.

A critical part of the bottle liquid filling Machine is its conveyor system, which transports empty bottles to the filling station and moves suffused containers to after stations for eclipsing and describing. The conveyor arrangement is outfitted with accompanying alterable speed controls to accommodate various container sizes and result speeds, guaranteeing smooth and continuous movement throughout the contents process.

The instrument panel serves as the command post of the motor, admitting manipulators to set and monitor differing limits of the contents process. This involves regulating fill capacities, configuring speed scenes for the messenger and contents heads, and monitoring the overall movement of the system in real-time. Modern control panels frequently feature instinctive interfaces accompanying touchscreen displays and programmable sanity controllers (PLCs) to expedite exact control and automation.

We are the best liquid filling machine manufacturer and also provide the Oral Liquid filling machine bottle price in India.

| Model Filling Type | ALFT-60 | ALFT-100 | ALFT-150 | ALFT-200 |

| Filling type | Dive-in | Dive-in | Dive-in | Dive-in |

| Grade | Automatic | Automatic | Automatic | Automatic |

| suitability | Water base liquids | Water base liquids | Water base liquids | Water base liquids |

| Bottle Diameter Range | Up to 100mm | Up to 100mm | Up to 100mm | Up to 100mm |

| Input/Output type | Manuel | Manuel | Manuel | Manuel |

| Pump Nos. | 2 | 4 | 6 | 8 |

| Filling Accuracy | ±1 | ±1 % | ±1 % | ±1 % |

| Output/Min | 50-60 Bottles | 80-110 Bottles | 130-150 Bottles | 180-200 Bottles |

| Dimensions( L*W*H) | N/A | N/A | N/A | N/A |

An Oral Liquid Filling Machines integrate advanced technology and accuracy engineering to automate the contents of filling oral medications, syrups, and different products into containers. We also have provided you with the Oral Liquid Filling Machine bottle price with affordable prices, so that every customer can get the facility to buy it. By combining efficient content methods with advanced control structures and safety features, these machines influence the production efficiency, consistency, and supervisory agreement required in the pharmaceutical, nutraceutical, cosmetic, and food and beverage industries.

What is the use of a bottle-filling machine?

The liquid bottle-filling machine is generally used in the pharmaceutical and food industry.

What is the oral liquid filling production line?

The Oral Liquid Line (oral liquid production line) including the suspension filling line consists of the production plant, washing, liquid filling, capping, and labeling machines.

What is the principle of a liquid filling machine?

This operates on the principle of liquid pressure filling. When the pressure is high, the liquid flows into the bottle using its weight.

What is the filling machine used for?

It is a packaging machinery to fill the product into bags, pouches, or containers such as bins or bottles.

Which pump is used in the filling machine?

Gear pumps are ideal for high-volume filling.

What is the bottle-filling process?

The first is equal air pressure filling. The liquid flows into the bottle based on its weight when the liquid reservoir’s pressure is equal to the bottle. In this process, the liquid flows into the bottle due to pressure

| Model | ALFT-60 | ALFT-100 | ALFT-150 | ALFT-200 |

| Filling Type | Dive-in | Dive-in | Dive-in | Dive-in |

| Grade | Automatic | Automatic | Automatic | Automatic |

| Suitability | Water base liquids | Water base liquids | Water base liquids | Water base liquids |

| Bottle Diameter Range | Up to 100mm | Up to 100mm | Up to 100mm | Up to 100mm |

| Input/output Type | Manuel | Manuel | Manuel | Manuel |

| Pumps Nos. | 2 | 4 | 6 | 8 |

| Filling Accuracy | ±1 % | ±1 % | ±1 % | ±1 % |

| Output/Min | 50-60 Bottles | 80-110 Bottles | 130-150 Bottles | 180-200 Bottles |

| Dimensions (L X W X H) | N/A | N/A | N/A | N/A |