World's Top Liquid Filling Machine Manufacturer | Laxmi Pharma Equipment

Laxmi Pharma is a highly acclaimed manufacturer of Liquid Filling Machines. The company has rich experience in designing and manufacturing high-performance filling solutions for the pharmaceutical, cosmetic, and food industries. Its machines are engineered to the highest standards of efficiency, precision, and reliability. Strong global presence serves customers across the USA, Canada, Kenya, and Bangladesh. Whether you’re looking for compact machines for small-scale operations or high-speed filling systems for large-volume production, Laxmi Pharma will definitely serve your needs to drive business further. Equipped with years of expertise and a commitment to innovation, we ensure that clients receive the best-in-class machinery that maximizes productivity while keeping topmost quality standards. Trust Laxmi Pharma for all your liquid filling needs, and experience the difference that quality and reliability can make in your manufacturing.

Types of Filling Machines Offered by Laxmi Pharma

1.Automatic / Semi-Automatic Ear / Eye Drop Liquid Filling Machine

It is meant for accurate, aseptic filling in small and large-sized productions of ear and eye drops. Compact design, effortless to work on, flexibility, and ease of installation are why this machine comes in handy to many pharmaceutical companies as an effective solution.

Key Features and Specifications

| Feature | Description |

| Model | EEDF-20 |

| Filling Range | 5ml to 50 ml |

| Nozzles | 2 to 8 |

| Filling Accuracy | ±1% |

| Operation Mode | Automatic and Semi-Automatic |

| Capacity | Up to 2400 bottles per hour |

| Material | Stainless Steel(SS316/SS304) |

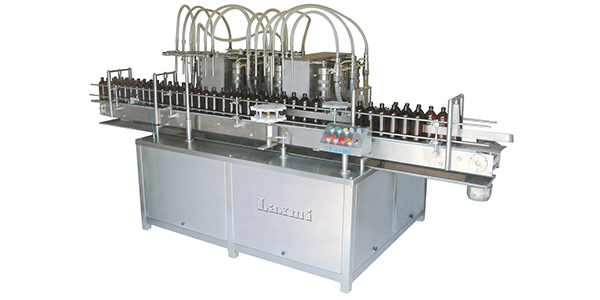

2.Oral Liquid Filling Machine Manufacturer- Bottle

Laxmi Pharma is a well-established manufacturer of liquid-filling machines. It specializes in manufacturing oral liquid bottle-filling machines, which fill high-speed and accurate syrups, suspensions, and other oral liquids into bottles with much precision.

Key Features and Specifications

| Feature | Description |

| Model | OLFM-100 |

| Filling Range | 10ml to 200 ml |

| Nozzles | 2 to 6 |

| Capacity | Up to 3000 bottles per hour |

| Material | Stainless Steel (SS316/SS304) |

| Additional | Drip-free Filling, Capping Integration |

3.The Role of Dry Powder Filling Machines in Injectable Manufacturing

Dry powder filling machines are very important in injectable manufacturing, ensuring sterile and accurate dosing of powdered drugs into vials or ampoules. The machines are designed to be precise and comply with global pharmaceutical standards.

Key Features and Specifications

| Feature | Description |

| Model | DPF-30 |

| Filling Range | 50 mg to 1 g |

| Filling Accuracy | ±2% |

| Output | Up to 2000 vials per hour |

| Material | SS316 |

| Applications | Injectable powders |

4.Injectable Liquid Filling Machine – For Vials

Laxmi Pharma’s injectable liquid filling machines are designed for pharmaceutical applications where sterility and precision are paramount. These machines fill liquid injectables into vials with utmost accuracy.

Key Features and Specifications

| Feature | Description |

| Model | ILFM-50 |

| Filling Range | 1ml to 50ml |

| Output | Upto 5000 vials per hour |

| Nozzles | 2 to 8 |

| Filling Accuracy | ±1% |

| Material | SS316 |

5.Automatic Auger Type Powder Filling Machine

The automatic auger-type powder-filling machine is designed for efficient filling of dry and fine powders in the food, pharmaceutical, and cosmetic industries. It delivers high-precision filling with negligible waste.

Key Features and Specifications

| Feature | Description |

| Model | ATPF-100 |

| Filling Range | 5 g to 200 g |

| Output | Up to 3000 containers per hour |

| Material | SS316/SS304 |

| Applications | Spices, dry chemicals, cosmetic powders |

| Additional features | Dust-free operation, fast changeovers |

6.Automatic Multi Head Ampoules Filling–Sealing Machine

This advanced machine is a leading solution for ampoule filling and sealing operations, ensuring high accuracy and sterility. It is suitable for liquid injectables and is favored by pharmaceutical manufacturers worldwide.

Key Features and Specifications

| Feature | Description |

| Model | AMHS- 150 |

| Filling Range | 2 to 6 |

| Output | Up to 15,000 ampoules per hour |

| Nozzles | 1 ml to 20 ml |

| Filling Accuracy | ±1% |

| Material | SS316 |

| Special Features | Gas Flushing, no ampoule no filling |

Why Laxmi Pharma?

Laxmi Pharma is one of the most renowned liquid-filling machine manufacturers in the industry. The organization is known for its latest technology and high engineering. Because of its quality, precision, and innovation, our clients in the USA, Canada, Kenya, and Bangladesh have always found a reliable source in us.

Key Advantages of Choosing Laxmi Pharma:

- Customized Solutions: Tailor-made machines to cater to the needs of different industries.

- Global Presence: Offers services in more than one country with local support.

- Robust Fabrication: Fabricated with highest-grade stainless steel with zero maintenance.

- Compliance: International standards for safety and efficiency.

- High Output: Machines built for maximum output with maximum efficiency.

Applications of Filling Machines

Laxmi Pharma’s high-tech filling machines find use in a wide range of sectors, including:

- Pharmaceuticals: Sterile liquids, powders, and injectables are filled.

- Food and Beverages: Sauces, syrups, and beverages are filled with accuracy.

- Cosmetics: Filling of creams, gels, and powders.

- Chemicals: Industrial chemicals and reagents are filled with precision.

Trusted by Industries Worldwide

Laxmi Pharma offers a comprehensive range of advanced filling solutions from ear/eye drop machines to fully automatic multi-head ampoule filling-sealing machines. Its expertise empowers businesses to achieve precision, durability, and efficiency in manufacturing.

For leading-edge filling solutions and unparalleled service, choose Laxmi Pharma premier liquid filling machine manufacturer strengthening industries worldwide- USA, Canada, Kenya, and Bangladesh.

FAQ’s

1.What is the function of the filling machine?

Filling machines draw liquid from a bulk supply vessel via a feed pipe, or from a hopper and allow the operator to determine and dispense specific quantities of the liquid into containers as required.

2.What is an Automatic/Semi-Automatic Ear/Eye Drop Liquid Filling Machine?

A device ensuring precision and efficiency in accurately filling ear/eye drop liquids into containers.

3.What makes a reliable Bottle Oral Liquid Filling Machine Manufacturer?

A reliable manufacturer ensures precision, durability, customization, and compliance with industry standards.

4.What is an Injectable Liquid Filling Machine – For Vials?

A specialized machine designed to accurately fill injectable liquids into sterile vials, ensuring precision and contamination-free operations in pharmaceutical manufacturing.

5.What is an Automatic Auger Type Powder Filling Machine?

An advanced machine designed for precise filling of powders into containers, ensuring consistency and minimizing wastage.

6.What is an Automatic Multi Head Ampoules Filling–Sealing Machine?

A high-speed machine designed for filling and sealing ampoules efficiently, ensuring precision, reliability, and contamination-free operation.

7.What industries can use Laxmi Pharma’s liquid filling machines?

Our machines cater to pharmaceuticals, cosmetics, and food industries for precise and efficient liquid filling solutions.